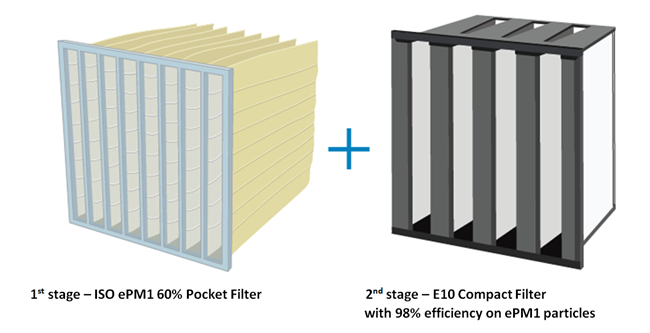

Download this helpful infographic on a recommended two-stage filtration upgrade.

Your building requires safety checks prior to reopening after a period of downtime. To aid you in your preparation, we compiled a list of steps that you can follow to feel confident in the cleanliness of your building.

- Clean and sterilize all floors, counters, and even the air according to suggestions from the European Ventilation Hygiene Association. More information you can find here.

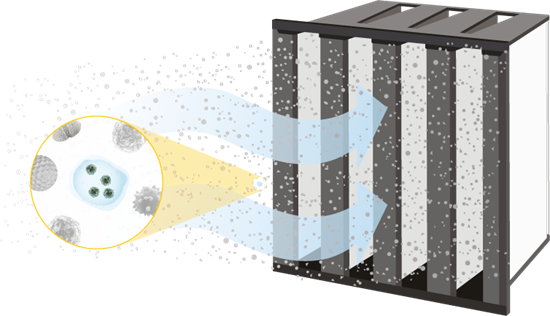

- Prior to running your HVAC system at normal capacity again, replace existing air filters with clean filters.

a. Safety First – Before replacing dirty air filters, first be sure to wear gloves, a mask, and safety glasses. As you slowly remove the current air filters, take care not to dislodge any of the dust and debris, which can otherwise re-enter the airstream inside your building.

b. Bag Disposal – Now that you have removed the dirty air filters, place them into bags and seal these bags as further protection against the collected dust and particles harming people who are exposed to them.

c. Clean Air Filters Installation – Place clean air filters inside the HVAC unit with the air flow arrow pointing toward the blower motor. You will find this air flow arrow on the frame of your air filter. - Do not operate locally recirculating air conditioning equipment (If possible), such as fan-coil units and induction units. These systems have typically very low efficiency filtration which will be minimal use against small droplet nuclei.

- Before reopening your business, ramp up your HVAC system to normal levels, allowing air to circulate for a couple of hours before people enter the building.

FHK Polska

FHK Polska PureMedion Kft.

PureMedion Kft. Elfa spol. s r. o.

Elfa spol. s r. o. Ecotip d.o.o.

Ecotip d.o.o.

![[Translate to Swedish:] [Translate to Swedish:]](/fileadmin/_processed_/8/8/csm_0ftkqil2_9a24bcce7b.png)

![[Translate to Swedish:] [Translate to Swedish:]](/fileadmin/_processed_/a/c/csm_Mar_25_Avoid_News_Feed_348-x-285-_1__ef69dcef75.png)